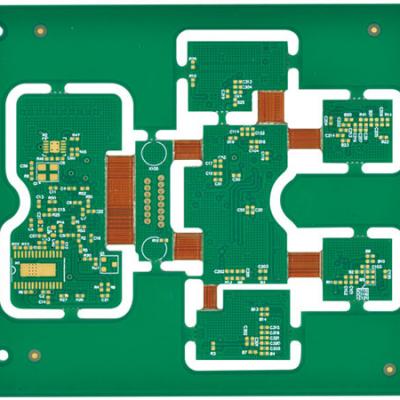

If you are planning to design a printed circuit board, you will discover there are many types of PCBs. There are single-layer PCBs, double-layer PCBs, and multilayer PCBs among many others. However, the two most popular circuit boards are the Two Layer and Four Layer PCBs.

Below is an outline that will help you understand and know the difference between 2 Layer printed circuit boards and 4 Layer printed circuit boards.

2 Layer Printed Circuit Board vs. 4 Layer Printed Circuit board

In PCBs, layers are very important. Layers are copper layers on the circuit board. A circuit board may need several copper layers to function properly.

For example, if a board needs more than two layers to perform its work, the layers can be increased by two to make it a 4 Layer PCB, a six-layer PCB, and so on.

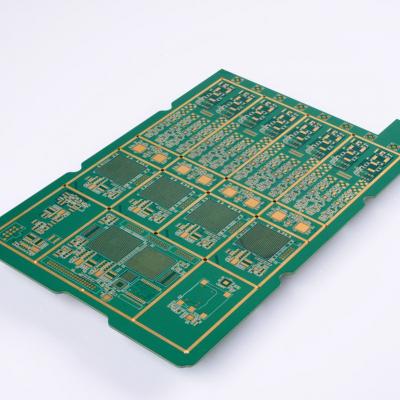

What is a 2 Layer (Double-Sided) Printed Circuit Board?

A 2 Layer PCB has two copper layers and it is known as a double-sided printed circuit board. Since it is two-sided, it provides mechanical support and can connect components on both sides.

2 Layer Printed Circuit board has two copper layers with a substrate material. Also, holes known as vias are drilled through the board. This allows circuits to be connected from one side of the board to the other.

Unlike single-layer printed circuit boards, double-layer PCBs have enough room for more components. Hence, they are more popular than single-layer PCBs.

Advantages of 2 Layer Printed Circuit Boards

*Lower cost - A Two-Layer PCB is cheaper than a Four-Layer circuit board. However, the manufacturing cost is determined by the number of units you plan to order.

*Easier design and production – a simpler design means you can get your circuit boards faster. If the design is not complex, manufacturing has fewer costly errors. Also, it is easier to repair a double-sided PCB than to repair a Four-Layer PCB.

Higher Volume – when dealing with mass production, it is vital to eliminate any unnecessary layers. Hence, 2-Layer is ideal since it can enhance production speed, efficiency, and cost.

*Short lead time – double-sided PCBs have an advantage over four layers and multilayer PCBs when it comes to lead time. Whether it is a small or large project, 2 Layer PCB takes a shorter lead time to make a prototype.

Disadvantages of 2 Layer PCBs

*Higher Weight and Larger Size – 2 Layer printed circuit boards are bulky and large to have room for leads and components. If you may want to fit your PCB into a compact space, you need to add more layers.

*Simplistic design – when you choose 2 Layer PCB, you sacrifice a lot of things. For example, you may not include whistles and bells. But with a 4 Layer printed circuit board, there is room for more components. However, a 2 Layer circuit board is just a simple design.

*Slower speed – when it comes to speed, the more layers you have, the higher the speed. Hence, in some projects, 2 Layers might not be enough to offer the speed you need.

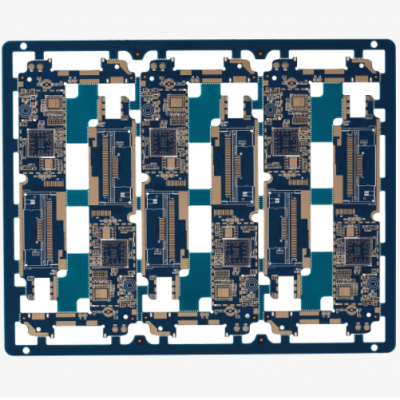

What is a 4-Layer Printed Circuit Board?

A 4 Layer PCB features four layers of copper. The layers are laminated together with substrates. The top layer and the bottom one are the signal layers. But the inner ones are the ground and supply planes.

4 Layer Printed Circuit Boards are more powerful than single-layer PCBs and 2 Layer PCBs. But even though they are great for complex projects and remarkable for their functionality, their cost is higher than their 2-layer counterparts.

Advantages of 4-Layer Printed Circuit boards.

*High quality – if you are looking for high quality, a 4 Layer circuit board is better than a 2 Layer PCB. So, the 4 Layer board will provide higher quality results if the cost is not a problem.

*Useful for many projects – if your project is complex, the extra layers of 4 Layer PCB will be so beneficial. Since it is possible to be creative and add extra components, the PCBs can be used for complicated projects.

*Increased durability – since the circuit board has many layers, it is more durable than a 2 Layer Printed Circuit board. Even though Four Layer PCBs are smaller than double-sided circuit boards, they are more substantial.

*Added power – another advantage of a 4 Layer PCB is the ability to handle more power. Hence, if you are not sure whether to have a 2 Layer PCB or a 4 Layer PCB, think of how much power the design needs.

*Smaller size and lighter weight – apart from being durable and extra power, 4 Layer Printed Circuit boards are small and very light. They are smaller and lighter than double-sided PCBs because they need less room for wiring and components.

Disadvantages of 4 Layer Printed Circuit Boards

*Complicated designs – when designing and producing a circuit board, the more layers you have, the more complicated the design will be. In addition, they need more time in the manufacturing process, such as CNC milling and lamination. It means the double for two layer PCB.

*Higher costs – You need more materials when designing and producing a 4 Layer Printed Circuit board. Hence, you will incur more costs than when producing a 2 Layer Printed Circuit Board. So, if cost is a problem, the best option is to reduce the number of layers.

*Complex repairs – 2 Layer PCBs have an advantage over 4 Layer PCBs when it comes to repairs. Any repair on the 4 Layer PCB is more complex and needs more time.

*Less availability of manufacturers – if your project is complex, finding a manufacturer might be challenging. So, when planning to produce 4 Layer PCBs, you might have issues getting a reliable manufacturer.

Bottom-Line

2 Layer Printed Circuit Board and 4 Layer Printed Circuit Boards are two types of boards that provide different functions. They are both beneficial for different types of projects. Therefore, the choice between the two depends on your projects and your budget.

But you need to understand that it is cheaper to produce a 2 Layer PCB because the design is less complicated and you require fewer materials. On the other hand, a 4 Layer circuit board is durable, superior, and performs better.

Shenzhen HongYuan Electronics Co.,Ltd

Shenzhen HongYuan Electronics Co.,Ltd