An Overview Of Constantan In Flexible Circuit Boards

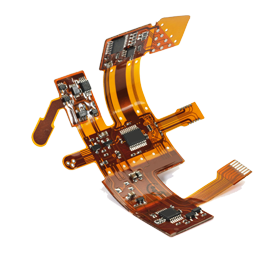

The electrical and thermal conductivity that copper creates makes it an obvious choice as a conductor in printed circuit board (PCB) construction, but in many applications that require flexible circuit boards, copper alloy metals can be far better to use. Some of those applications include using conditions of extreme heat or cold, where copper’s low resistance becomes a liability. Constantan is an alloy consisting of 55% copper and 45% nickel, this is one of several metals that has been proven effective for its higher resistance and lower thermal conductivity. Constantan used in flexible PCBs is an ideal choice for many applications.

Constantan is the oldest and most commonly used of what are known as “strain gauge alloys,” which are metals used to measure how materials react to stress from various forces. These alloys have become very important to the construction of many flexible circuits. Flex circuit boards are often designed for technologies that operate in harsh environments and require a high density of circuitry in enclosures with limited space. The market demand for flex PCBs that can withstand high temperatures has increased as such components are routinely used in oil drilling, semiconductor processing, medical diagnostic technology, and the construction of airplanes and defense systems.

Flexible circuits are small and light when compared with rigid PCBs and cable bundles. Flex circuits fit into many tight spaces, they can also bend around corners, and can better withstand vibration, high pressure, and extreme temperatures. They take up 75% less space than rigid PCBs and can be designed to accept virtually any necessary connectors. This makes flexible circuit boards ideal for many defense, medical, and aerospace technologies, like cryogenics, infrared imaging, and the construction of satellites, which often must withstand temperatures down to -150°F and up to 550°F.

Flex circuits can be printed single- or double-sided, multi-layer, or in combinations of rigid and flexible boards. All require unique processing in their fabrication. The choice for many designs includes thin, durable, material like Constantan in flexible PCBs. Constantan’s resistance remains stable across an extreme range of temperatures as well as in high pressure and other stressful situations. These qualities, plus its relatively low cost, have made Constantan foil a desirable conductive material for flex PCBs designed for hostile operating environments and rugged electronics.

In addition to solving the problem of thermal conductivity due to extreme external temperatures, Constantan in flexible PCBs can help maintain long-term reliability in situations when internal temperatures remain high. As electronics become faster and smaller, they require innovative designs and materials to deal with heat buildup. Along with the effective design of heat sinks and air flows, the use of Constantan as a conductor can lower thermal conductivity in flexible PCBs.

In addition to solving the problem of thermal conductivity due to extreme external temperatures, Constantan in flexible PCBs can help maintain long-term reliability in situations when internal temperatures remain high. As electronics become faster and smaller, they require innovative designs and materials to deal with heat buildup. Along with the effective design of heat sinks and air flows, the use of Constantan as a conductor can lower thermal conductivity in flexible PCBs.

Shenzhen HongYuan Electronics Co.,Ltd

Shenzhen HongYuan Electronics Co.,Ltd