PTFE

PTFE meaning

Polytetrafluoroethylene is generally called "non-stick coating" or "easy-to-clean wok material"; it is a synthetic polymer material that uses fluorine to replace all hydrogen atoms in polyethylene. This material is resistant to acid and alkali, and various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance, and its friction coefficient is extremely low, so it can not only be used for lubrication, but also can be used for individual coatings.

Polytetrafluoroethylene is generally called "non-stick coating" or "easy-to-clean wok material"; it is a synthetic polymer material that uses fluorine to replace all hydrogen atoms in polyethylene. This material is resistant to acid and alkali, and various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance, and its friction coefficient is extremely low, so it can not only be used for lubrication, but also can be used for individual coatings.Advantages and disadvantages of polytetrafluoroethylene

The use of polytetrafluoroethylene is excellent

High temperature resistance: the working temperature can reach 250°C.

Low temperature resistance: It has good mechanical toughness; even if the temperature drops to -196°C, it can maintain an elongation of 5%.

Corrosion resistance: Inert to most chemicals and solvents, resistant to strong acids and alkalis, water and various organic solvents.

Weather resistance: has the best aging life among plastics.

Non-toxic: It is physiologically inert, and there is no adverse reaction when it is implanted in the body for a long time as an artificial blood vessel and organ.

Non-adhesive: It is the smallest surface tension in solid materials and does not adhere to any substance.

High lubrication: the lowest coefficient of friction among solid materials

The relative molecular weight of polytetrafluoroethylene is relatively large, ranging from hundreds of thousands to over 10 million, and generally to millions (the degree of polymerization is on the order of 104, while polyethylene is only 103). Generally, the degree of crystallinity is 90-95%, and the melting temperature is 327-342°C. The CF2 units in the PTFE molecule are arranged in a zigzag shape. Since the radius of the fluorine atom is slightly larger than that of hydrogen, the adjacent CF2 units cannot completely follow the trans-cross orientation, but form a helical twisted chain, and the fluorine atoms almost cover surface of the entire polymer chain. This molecular structure explains the various properties of PTFE. When the temperature is lower than 19°C, a 13/6 helix is formed; at 19°C, a phase transition occurs, and the molecules untie slightly to form a 15/7 helix.

Shortcomings of PTFE

PTFE has "cold flow". That is, the plastic deformation (creep) of material products under long-term continuous load, which brings certain restrictions to its application. For example, when PTFE is used as a gasket, the bolts are tightened tightly for tight sealing, so that when a certain compressive stress is exceeded, the gasket will produce "cold flow" (creep) and be flattened. These shortcomings can be overcome by adding appropriate fillers and improving the structure of parts.

PTFE has outstanding non-stick properties, which limits its industrial application. It is an excellent anti-adhesive material, which makes it extremely difficult to adhere to the surface of other objects.

The linear expansion coefficient of PTFE is 10 to 20 times that of steel, which is larger than most plastics, and its linear expansion coefficient changes irregularly with the change of temperature. When applying PTFE, if you do not pay enough attention to this aspect of performance, it is easy to cause losses.

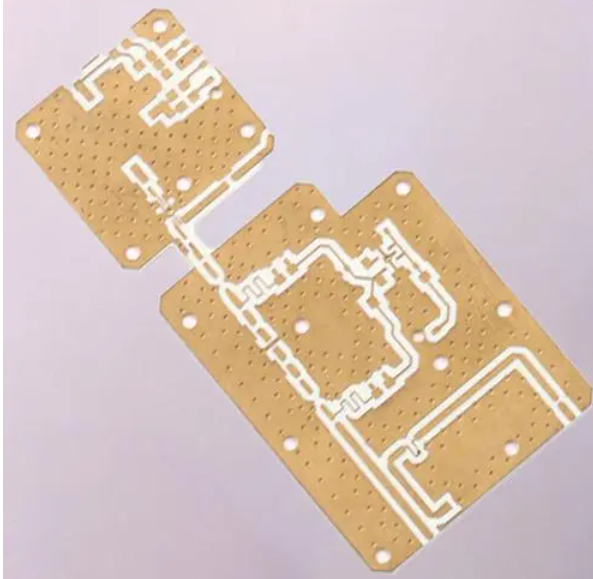

PTFE sheet

Overview of PTFE sheet

There are two types of PTFE boards: molding and turning. At present, each line can also manufacture these two kinds of boards. The molded board is formed by molding PTFE resin at room temperature, and then sintered and cooled. PTFE turning board is made of PTFE resin after compaction, sintering and rotary cutting. Its products are widely used and have extremely superior comprehensive properties: high and low temperature resistance (-192°C-260°C), corrosion resistance (strong acid, strong alkali, aqua regia, etc.), weather resistance, high insulation, high lubrication, non-adhesion, Non-toxic and other excellent characteristics. Polytetrafluoroethylene (English abbreviation is Teflon or [PTFE, F4]), known as/commonly known as "Plastic King", Chinese trade name ""Teflon", "Teflon", "Teflon" Teflon "," Teflon " (teflon), etc.

Polytetrafluoroethylene board is a polymer compound formed by polymerization of tetrafluoroethylene, and its simplified structure is -[-CF2-CF2-]n-, which has excellent chemical stability and corrosion resistance (PTFE Abbreviated as PTFE or F4, it is one of the most corrosion-resistant materials in the world today. "Plastic King" is commonly known as polytetrafluoroethylene. It is a plastic with the best corrosion resistance. It is not affected by known acids, alkalis, The corrosion of salt and oxidant, even the most powerful aqua regia is helpless to it, so it is named plastic king, except for molten metal sodium and liquid fluorine, it can resist all other chemicals, and is widely used in various needs to resist acids, alkalis and organic solvents. Excellent sealing performance, high lubrication and non-stickiness, electrical insulation and good aging resistance, excellent temperature resistance (can work for a long time at a temperature of +250°C to -180°C). PTFE itself is not toxic to humans , but may cause cancer during production.

The use of polytetrafluoroethylene board

At present, various PTFE products have been widely used in chemical industry, machinery, electronics, electrical appliances, military industry, aerospace, environmental protection and bridges and other fields and play a vital role.

Tetrafluoroethylene board is suitable for the temperature of -180℃~+250℃. It is mainly used as electrical insulation materials and linings for contact with corrosive media, supporting sliders, rail seals and lubricating materials. It is used in light industry by rich cabinet furniture. , Widely used in aviation, military and other heavy industries; machinery, construction, traffic bridge sliders, guide rails; anti-sticking materials in printing and dyeing, light industry, textile industry, etc. Chemical, pharmaceutical, dye industry containers, storage tanks, reaction tower kettles, anti-corrosion lining materials for large pipelines and other fields, it is a veritable universal product.

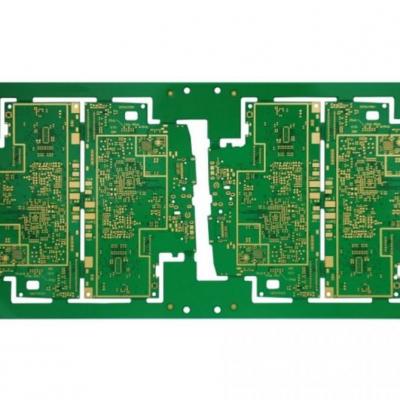

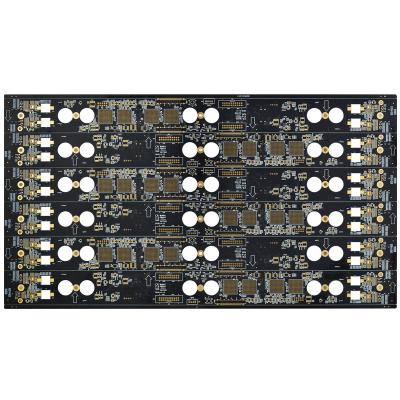

rpttechpcb is Professional production low-cost PCB,Cheap PCB, Low price for PCB,94V0

Shenzhen HongYuan Electronics Co.,Ltd

Shenzhen HongYuan Electronics Co.,Ltd