1. What is LED placement machine

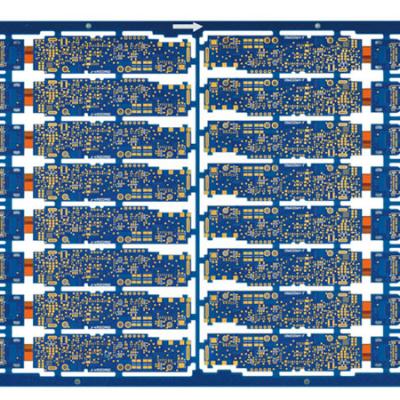

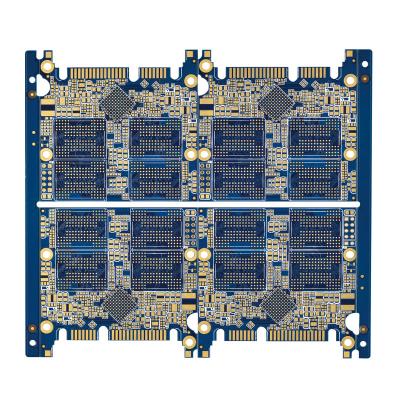

The LED placement machine is a kind of SMT placement equipment specially designed and customized for the LED industry. This kind of equipment does not require high precision, but requires high speed. The LED placement machine can be used to realize the assembly of large quantities of LED circuit boards, such as LED lamp beads, LED lamp tubes, LED bulb lamps, downlights, spotlights, panel lights...etc. The mainstream application of the LED placement machine should be to mount large-area PCB boards, meet the online requirements, and ensure its speed.

2. What is a smt placement machine

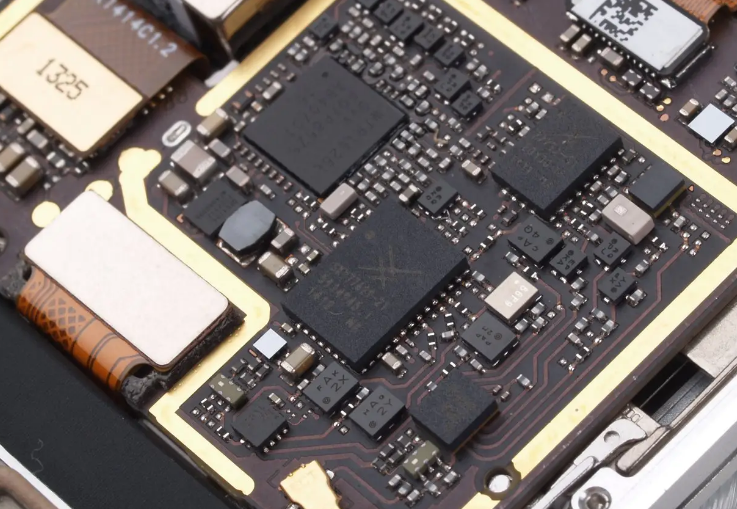

SMT placement machine, also known as "mounting machine", "Surface Mount System" (Surface Mount System) is a high-precision mechatronics equipment. It realizes the fast and accurate mounting of SMC/SMD components to the designated pad position of the PCB board without damaging the components and the printed circuit board through functions such as suction-displacement-positioning-placement. Moreover, SMT placement machines have certain requirements for the cleanliness, humidity, and temperature of the environment for equipment and process materials.

3. The difference between LED placement machine and SMT placement machine

SMT, including all the components of the LED patch, in simple terms, the working principle of the current LED placement machine and the SMT placement machine is the same, but there are some differences in the scope of application of the two. The LED placement machine is specially used in the LED industry for sticking lights. Broadly speaking, the LED placement machine is one of the SMT placement machines.

Fourth, the working principle of the led placement machine

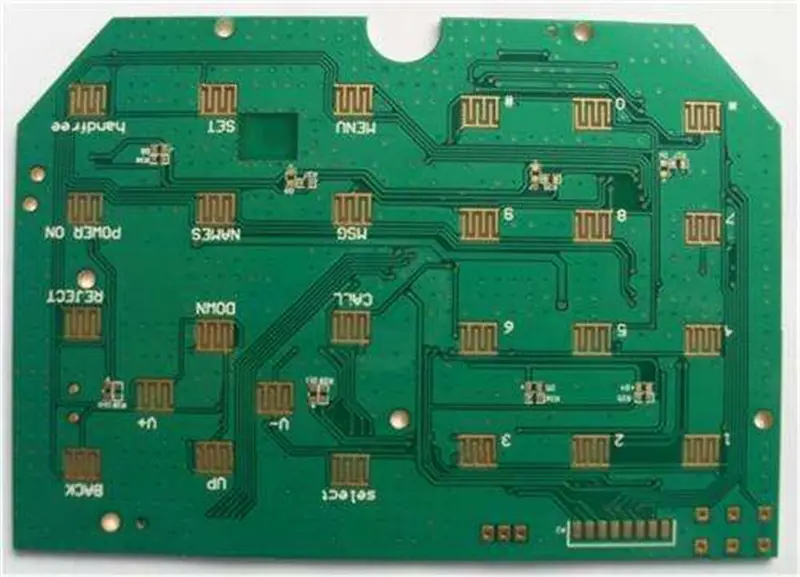

The working principle of the LED placement machine is the same as that of the ordinary placement machine. It is mainly composed of a placement head and a static lens. First, the LED placement head sends the LED lamp components to the PCB board according to the parameters such as the package type and component number of the imported LED lamp components. Grab the suction nozzle and pick up the components at the corresponding position; secondly, after the lens detects, recognizes and centers the sucked LED light according to the visual processing program, the placement head mounts the LED light to the corresponding position on the PCB board. This is the simple working principle of the LED placement machine.

The LED placement machine is marked with Mark on important components such as the placement spindle, dynamic/static lens, nozzle holder, and feeder. Machine vision can automatically calculate the coordinates of these Mark center systems, establish the conversion relationship between the coordinate system of the LED placement machine and the coordinate system of the PCB and mounted LED lights, and calculate the precise coordinates of the movement of the LED placement machine; the placement head according to The package type, component number and other parameters of the imported LED lights are grabbed to the corresponding position to grab the suction nozzle and pick up the components; the lens detects, recognizes and aligns the sucked LED lights according to the visual processing program; after the centering is completed, the placement head puts the LED The lamp is mounted to the predetermined position on the PCB. The actions of this series of LED lamp recognition, alignment, detection and placement are all automatically completed by the industrial computer after obtaining relevant data according to the corresponding instructions and instructing the control system. This series of actions is the detailed working principle of the LED placement machine.

The LED placement machine mainly needs to meet the mounting accuracy requirements of 3014, 2835, 3528 and 5050, 5630, 5730 lamp beads. Compared with the processing accuracy of traditional placement machines, LED placement machines have relatively low requirements. However, the LED placement machine pays more attention to performance, that is, the stability, speed, operability and size requirements of the machine operation.

Shenzhen HongYuan Electronics Co.,Ltd

Shenzhen HongYuan Electronics Co.,Ltd